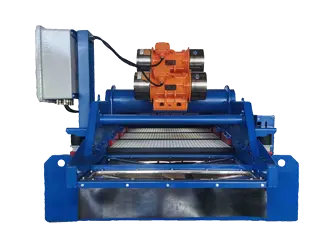

The solid control equipment for sale in our solid control oil drilling company is specialized machinery used in drilling operations to separate and remove solid particles from drilling fluids, enhancing efficiency and safety.

Efficiency: BZ solids control equipment helps to remove unwanted solids from the drilling fluid, which can increase the drilling speed and reduce the wear on the drilling equipment.

Cost-Effective: By reconditioning and reusing drilling fluid, solid control equipment can significantly reduce the cost of drilling operations. It minimizes waste disposal and the need for fresh drilling fluid.

Environmental Protection: Our solids control equipment for sale helps to minimize the environmental impact of drilling operations. It reduces the amount of waste generated and ensures that the drilling fluid is properly treated before disposal.

Solids control equipment works by using a series of machines to separate solids from drilling fluids. The process begins with a shale shaker, which uses a vibrating screen to filter out larger particles. The fluid then moves to a desander and desilter, which use centrifugal force to remove smaller particles. A decanter centrifuge is used for the final stage of separation, spinning the fluid at high speeds to separate even the smallest particles. The cleaned fluid is then recycled back into the drilling process, reducing waste and saving costs.

Email: sales@bzgukong.com

Email: sales@bzgukong.com

Call Us: 0316-5166559

Call Us: 0316-5166559

Address: Xiangfeng Street, Train Station Road, Sanhe, Hebei, China

Address: Xiangfeng Street, Train Station Road, Sanhe, Hebei, China