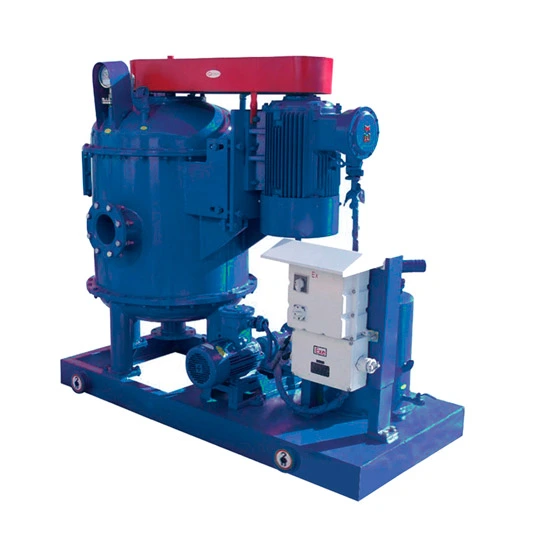

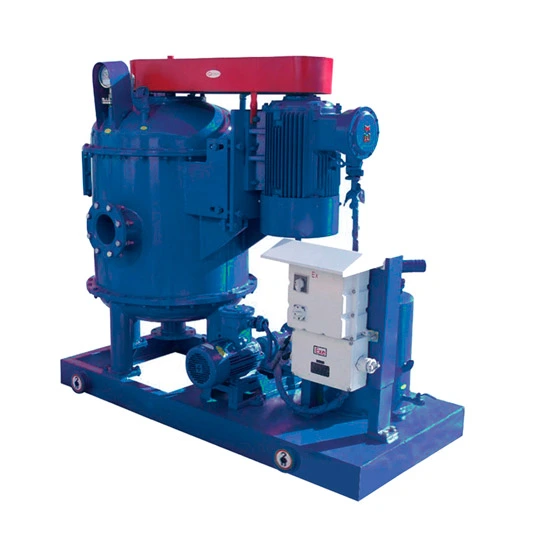

BZ vacuum tank degasser can effectively remove gases from drilling fluid, prevent blowout and safety accidents, and maintain mud system stability and operational safety.

Vacuum degassing systems mainly remove small gas bubbles (such air, methane, H2S, CO2, etc.) entrained in drilling fluid, and are often used as the second stage separation equipment of solid control equipment system.

The drilling fluid is pulled into the degasser tank by vacuum action and distributed to the gas-separation layers through orifice in the central pipe. Under vacuum conditions, gas bubbles develop in the drilling fluid. The fluid accelerates and hits the separation layers and tank wall, releasing entrained gas as the bubbles burst. The water ring vacuum pump vents the gas away to a safe place, while the degassed fluid is sent to the next tank for additional treatment.

Self-priming no need feeding pump.

High efficiency more than 95%.

Anticorrosive painting inside for longer service life.

Electrical components: ABB, Siemens, Schneider.

Compact design and small footprint.

Ex equipment design & manufacturing.

Can be used as high power mud agitator.

Can be equipped with level monitor for safer operation.

| Model | BZCQ240 | BZCQ270 | BZCQ300 | BZCQ360 |

| Tank Diameter | 700mm | 800mm | 900mm | 1000mm |

| Capacity (m³/h) | 240 (880gpm) | 270 (990gpm) | 270 (1100gpm) | 270 (1320gpm) |

| Vacuum Degree | -0.03 ~ -0.045MPa | |||

| Transmission ratio | 1.68 | 1.68 | 1.68 | 1.72 |

| Eficiency | ≥95% | |||

| Main Motor Power | 15kW (20hp) | 22kW (30hp) | 30kW (41hp) | 37kW (50hp) |

| Vacuum pump Power | 2.2kW (3hp) | 3kW (4hp) | 4kW (5hp) | 7.5kW (10hp) |

| Rotation Speed(RPM) | 860 | 870 | 876 | 880 |

| EX Standard | ExdII Bt4 / IECEX / ATEX | |||

| Weight | 1150kg | 1450kg | 1860kg | 2500kg |

| Dimension L*W*H (mm) | 1750 x 860 x 1500 | 2000 x 1000 x 1670 | 2250 x 1330 x 1650 | 2400x 1500 x 1850 |

Email: sales@bzgukong.com

Email: sales@bzgukong.com

Call Us: 0316-5166559

Call Us: 0316-5166559

Address: Xiangfeng Street, Train Station Road, Sanhe, Hebei, China

Address: Xiangfeng Street, Train Station Road, Sanhe, Hebei, China