In the oil and gas drilling industry, the efficiency of the drilling process is paramount. Among the myriad of tools and equipment that facilitate this efficiency, the desilter holds a place of significant importance. This article delves into the various aspects of a desilter for sale, aiming to provide a comprehensive understanding of its purpose, functionality, operation, and maintenance.

A desilter is a critical piece of solids control equipment used in drilling operations. Its primary function is to remove finer solid particles—specifically, those in the range of 15 to 44 microns—from the drilling fluid, or "mud". This is achieved through a series of hydrocyclones that leverage centrifugal force to efficiently separate these fine particles from the fluid.

Desilters are typically positioned downstream from a desander, another piece of solids control equipment designed to eliminate larger particles. While the desander handles particles ranging from 45 to 74 microns, a desilter further polishes the drilling fluid, ensuring that even finer particles are extracted before the fluid is recirculated.

The primary function of a desilter is to enhance drilling fluid performance by removing finer solid particles. The effectiveness of the drilling process greatly relies on the cleanliness of the drilling fluid. Here's how a desilter contributes to this:

Particle Size Reduction

During drilling, various types of rocks and sediments are broken down and mixed with the drilling fluid. While larger particles are managed by other equipment like shale shakers and desanders, the desilter focuses on capturing particles that are smaller but still significant enough to affect the drilling process negatively.

Optimization of Drilling Fluid

Clean drilling fluid ensures better lubrication, cooling, and stability of the drill bit and the wellbore. By removing fine solids, a desilter helps maintain the rheological properties of the drilling fluid, such as viscosity and density. This optimization is vital for the efficient and safe operation of drilling equipment.

Minimized Wear and Tear

A desilter also plays an indirect role in reducing the wear and tear of downhole and surface equipment. Fine particles can be abrasive, accelerating the rate at which equipment, including mud pumps and drill bits, degrade. By eliminating these particles, a desilter extends the life span of the equipment and reduces maintenance costs.

Environmental Impact

Efficient solids control reduces the environmental footprint of drilling activities. Fewer drilling fluids are wasted, and cleaner fluids mean that environmental discharges are less contaminated. This contributes to a more sustainable drilling operation.

Understanding how a desilter operates involves delving into the mechanics and principles of the hydrocyclone technology it employs.

Hydrocyclone Technology

A desilter works on the principle of centrifugal separation. The drilling fluid, laden with solid particles, is pumped into the hydrocyclone—a conical device. Under the influence of high-speed rotation, the fluid is subjected to centrifugal force.

Separation Process

As the fluid rotates within the hydrocyclone, the solid particles, being denser than the fluid, are flung outward and downward. They spiral along the inner walls of the hydrocyclone and are discharged through a small outlet at the bottom, known as the underflow. Meanwhile, the cleaner fluid moves upward and exits through the top outlet, known as the overflow.

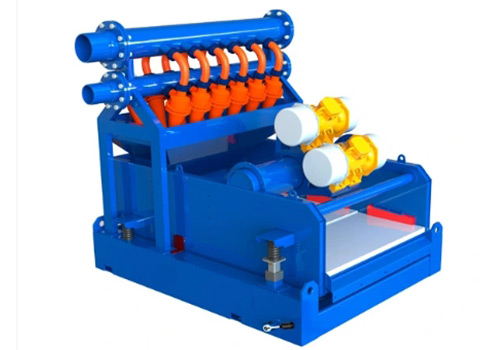

Multiple Hydrocyclones

Most desilters are equipped with an array of hydrocyclones, typically ranging from four to sixteen, depending on the required capacity and efficiency. This arrangement allows for the handling of larger volumes of fluid and higher separation efficiency, as each hydrocyclone works in parallel.

Integration with Drilling Systems

Desilters are integrated into the drilling fluid circulating system, positioned after the desander and before finer filtration devices like centrifuges. The placement ensures the progressive and efficient removal of solids, with each stage handling a specific particle size range.

Ensuring that a desilter functions optimally over an extended period requires diligent maintenance practices. Here are some key aspects of desilter maintenance:

Regular Inspections

Routine inspections are crucial to identify wear, tear, or potential failures. Inspecting the hydrocyclones for signs of abrasion, damage, or clogging ensures that each unit operates at peak efficiency. Regular checks help in preemptively addressing issues before they escalate into significant problems.

Cleaning and Flushing

Over time, the buildup of solids can lead to clogging within hydrocyclones and connecting pipelines. Regular cleaning and flushing ensure that there's no obstruction to fluid flow and the separation process remains unhindered. Some desilters are designed with automatic flushing systems to facilitate easy maintenance.

Wear and Tear Management

Hydrocyclones and other components are subject to significant abrasion due to the high-speed rotation and handling of solid-laden fluids. Using wear-resistant materials for these parts and replacing worn-out components promptly are vital. Regular monitoring of parts like liners and nozzles helps in extending the equipment's life.

Calibration and Adjustment

Ensuring optimal performance may also require recalibrating and adjusting the hydrocyclones periodically. Factors like feed pressure, the apex size of the hydrocyclone, and the cone angle can affect the separation efficiency. Field adjustments based on performance indicators help in maintaining optimal functioning.

Lubrication and Mechanical Maintenance

Desilters, like any industrial equipment, have mechanical parts that require regular lubrication and maintenance to avoid mechanical failures. Proper lubrication of moving parts, checking seals and bearings, and ensuring that all mechanical components are in good working order are part of routine maintenance.

Documentation and Record Keeping

Keeping detailed records of maintenance activities, inspections, and part replacements is essential. This documentation helps in tracking the performance over time and planning future maintenance schedules efficiently. It also aids in troubleshooting recurring issues and implementing preventive measures.

A desilter from BZ solid control oil drilling company plays an indispensable role in the drilling operations by efficiently removing fine solid particles from the drilling fluid. Its contribution to optimizing drilling fluid, minimizing equipment wear and tear, and reducing environmental impact cannot be overstated. Understanding its operation, the hydrocyclone technology it employs, and the importance of regular maintenance provides a clear picture of why the desilter is a crucial component in the drilling industry. Ensuring the optimal performance and longevity of desilters through diligent maintenance practices leads to more efficient, cost-effective, and sustainable drilling operations.